Electricity Generation and Distribution

What Is Electricity?

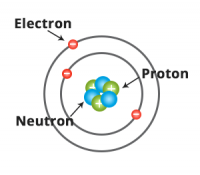

Electricity is a form of energy that starts with atoms. Atoms are too small to see, but they make up everything around us. All atoms are composed of subatomic particles, among which are the charged particles known as electrons and protons. Protons, which are found in the nucleus of an atom, carry a positive charge (+). Electrons, which spin around the center of an atom, carry a negative charge (-). Neutrons also exist in the nucleus of a typical atom and are uncharged.

Electricity is a form of energy that starts with atoms. Atoms are too small to see, but they make up everything around us. All atoms are composed of subatomic particles, among which are the charged particles known as electrons and protons. Protons, which are found in the nucleus of an atom, carry a positive charge (+). Electrons, which spin around the center of an atom, carry a negative charge (-). Neutrons also exist in the nucleus of a typical atom and are uncharged.

Electricity is a form of energy that is associated with the buildup and movement of electrons and protons. Electricity can be created by forcing electrons to flow from atom to atom. The force or push of electricity is measured in volts. Electrical systems of most homes and office have 120 volts.

How Electricity Is Generated

Most electricity in the U.S. is generated using coal, oil, natural gas, nuclear energy, or hydropower. Some production is done with alternative fuels like geothermal energy, wind power, biomass, solar energy, or fuel cells.

A majority of the electricity is produced at power plants with the use of steam turbines. Mechanical energy is changed into electrical energy by using various energy sources such as coal, natural gas, and oil. These fuels heat water in a boiler to produce steam. The steam, under tremendous pressure, is used to turn a series of blades mounted on a shaft turbine. The force of the steam rotates a shaft that is connected to a generator. The spinning turbine shafts turn electromagnets that are surrounded by heavy coils of copper wire inside generators. This creates a magnetic field, which causes the electrons in the copper wire to move from atom to atom, creating electricity.

A majority of the electricity is produced at power plants with the use of steam turbines. Mechanical energy is changed into electrical energy by using various energy sources such as coal, natural gas, and oil. These fuels heat water in a boiler to produce steam. The steam, under tremendous pressure, is used to turn a series of blades mounted on a shaft turbine. The force of the steam rotates a shaft that is connected to a generator. The spinning turbine shafts turn electromagnets that are surrounded by heavy coils of copper wire inside generators. This creates a magnetic field, which causes the electrons in the copper wire to move from atom to atom, creating electricity.

The voltage produced by a generator depends upon the number of turns in its coils, the strength of the magnet, and the rate at which the magnet turns. The more turns in the coils, the more voltage is produced.

How Electricity Is Distributed

Power plants do not store electricity, so it is constantly being made and then distributed. Utility companies have to anticipate demand for electricity and distribute it to consumers.

Electricity can be distributed most efficiently at very high voltage. Transformers are used to “step up” or “step down” the voltage along the system of power lines that carry electricity to consumers.

First, the voltage of the electricity produced by a generator in the power plant is “stepped up” when it travels through a secondary coil of a transformer that has far more turns of wire than the primary coil. Each charge that passes through that coil then has more energy than the charges in the primary coil. The current therefore has an enormous voltage when it leaves the secondary coil and then travels through the system of cables and wires from the power plant into the transmission grid.

These transmission lines carry the electricity across long distances to substations. A substation has transformers that “step down” the high-voltage electricity into lower voltage electricity. At a substation, the current passes through a transformer with a secondary coil that has fewer turns of wire, which reduces it to only a medium-high voltage.

These transmission lines carry the electricity across long distances to substations. A substation has transformers that “step down” the high-voltage electricity into lower voltage electricity. At a substation, the current passes through a transformer with a secondary coil that has fewer turns of wire, which reduces it to only a medium-high voltage.

From the substation, distribution lines carry the electricity to other transformers on utility poles or on the ground that reduce the voltage so it can be used in homes, offices, stores, and factories. A cable then carries the electricity from the distribution wires to the house through a meter box. The meter measures how much electricity the people in the house use.

From the meter box, wires run through the walls to outlets and lights. The electricity is always waiting in the wires to be used. The amount of electricity in the lines must be kept at a constant electrical pressure to provide enough power for the appliances and equipment that will use it. A second set of wires carries the current back to the generator in the power plant. These return wires are necessary because electric current must travel in a loop, or a closed circuit.

Natural Gas Formation, Exploration, and Distribution

What Is Natural Gas?

Natural gas, also known as methane, is a colorless, odorless, clean-burning fossil fuel that provides about one-fifth of the energy used in our country. It is clean, easy to transport, and convenient to use. Natural gas is used for heating, cooling, lighting, cooking, as a fuel for home appliances and the production of electricity, and for many industrial uses.

Natural gas, also known as methane, is a colorless, odorless, clean-burning fossil fuel that provides about one-fifth of the energy used in our country. It is clean, easy to transport, and convenient to use. Natural gas is used for heating, cooling, lighting, cooking, as a fuel for home appliances and the production of electricity, and for many industrial uses.

Most geologists believe that natural gas was formed thousands of years ago when plants and animals died and their decomposed remains were deposited with mud and silt. With time they were covered by sediments and were compressed by the weight of the sedimentary layers. As a result of intense heat and pressure the organic materials were transformed into natural gas and oil. Some scientists believe that deep gas pockets were formed during the creation of the earth.

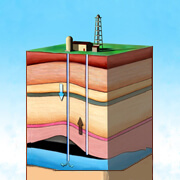

Natural gas is found trapped in impermeable layers of rock in different underground formations such as shale formations, coal seams, sandstone beds, and deep, salt-water aquifers.

How Natural Gas Is Obtained

Before drilling, geologists and geophysicists are employed to try to find the right conditions for a gas or oil deposit. Geologists employ sophisticated technology to try to find pockets of natural gas below the earth’s surface. They need to have a clear picture of what is below the earth’s surface.

They use seismology, a process in which shock waves (like tiny earthquakes) are passed through hidden rock layers. The waves that are reflected back to the surface are captured as digital recordings, which are then transformed into a visual representation of what is below the earth’s surface.

High-speed computers are also used to help develop three-dimensional underground maps that help try to locate gas deposits. Computers are also used to analyze satellite images of surface rocks and terrain.

Magnetometers are used to get measurements of magnetic characteristics of the crust. This device is able to measure small changes in the Earth’s magnetic field at the surface, which indicates what kind of rock formations might be present underground.

The only way to actually find the gas deposits is to drill. Gas wells are drilled thousands of feet into the earth’s crust to extract natural gas from pockets in underground rock formations or from deep, salt-water aquifers, and then big pumps bring it to the surface.

The location of the gas pocket and the type of rock formation determine what type of drilling equipment is used. Cable drilling rigs are used for shallow formations, and rotary drilling rigs are employed for deeper formations. Drilling offshore requires a base to be built, whereas onshore drilling uses land for a base. The floating drilling platform needs a mechanism for attaching it to the base of the ocean floor,and the pitching and rolling of the ocean must also be factored into the design.

How Natural Gas Is Distributed

After processing, where an odor is added to help people identify gas leaks, natural gas is compressed and distributed through pipelines to storage facilities. The gas is then sent from smaller pipes to homes, offices, stores, and factories. Natural gas is used for heating, lighting, cooling, and cooking, and as a fuel for home appliances and for the production of electricity.

After processing, where an odor is added to help people identify gas leaks, natural gas is compressed and distributed through pipelines to storage facilities. The gas is then sent from smaller pipes to homes, offices, stores, and factories. Natural gas is used for heating, lighting, cooling, and cooking, and as a fuel for home appliances and for the production of electricity.

Alternative Energy Sources

Alternative energy sources are resources that are constantly replaced and are usually less polluting. They are not the result of the burning of fossil fuels or the splitting of atoms. Alternative energy sources include biomass, geothermal, hydroelectric, solar, wind power, fuel cells, ocean thermal energy conversion, tidal energy, and wave energy.

Biomass is renewable energy that is produced from organic matter. Biomass fuels include wood and forest and mill residues, animal waste, grains, agricultural crops, and aquatic plants. These materials are used as fuel to heat water for steam or processed into liquids and gases, which can be burned to do the same thing. Currently, biomass (including wood, waste, and biofuels) constitutes almost 44% of all renewable energy consumed in the US.

Biomass is renewable energy that is produced from organic matter. Biomass fuels include wood and forest and mill residues, animal waste, grains, agricultural crops, and aquatic plants. These materials are used as fuel to heat water for steam or processed into liquids and gases, which can be burned to do the same thing. Currently, biomass (including wood, waste, and biofuels) constitutes almost 44% of all renewable energy consumed in the US.

Geothermal energy uses heat from within the earth. Wells are drilled into geothermal reservoirs to bring the hot water or steam to the surface. The steam then drives a turbine to generate electricity in geothermal plants. In some places, this heat is used directly to heat homes and greenhouses, or to provide process heat for businesses or industries. The United States leads the world in electricity generation with geothermal power, with most geothermal resources concentrated in the western part of the country. With technological improvements, much more power could be generated from hydrothermal resources. Scientists have been experimenting by pumping water into the hot dry rock that is 3-6 miles everywhere below the earth’s surface for use in geothermal power plants.

Geothermal energy uses heat from within the earth. Wells are drilled into geothermal reservoirs to bring the hot water or steam to the surface. The steam then drives a turbine to generate electricity in geothermal plants. In some places, this heat is used directly to heat homes and greenhouses, or to provide process heat for businesses or industries. The United States leads the world in electricity generation with geothermal power, with most geothermal resources concentrated in the western part of the country. With technological improvements, much more power could be generated from hydrothermal resources. Scientists have been experimenting by pumping water into the hot dry rock that is 3-6 miles everywhere below the earth’s surface for use in geothermal power plants.

Hydroelectric (hydropower) energy employs the force of falling or moving water to drive turbine generators to produce electricity. Traditional hydropower involves dams built on rivers to trap water and release it through a turbine to generate electricity. Most traditional hydropower facilities are found in hilly or mountainous areas. New hydropower uses energy from the natural movement of water to produce electricity without changing the water flow. For example, the constant flow of water in a river can spin the blades of underwater turbines to produce electricity.

Hydroelectric (hydropower) energy employs the force of falling or moving water to drive turbine generators to produce electricity. Traditional hydropower involves dams built on rivers to trap water and release it through a turbine to generate electricity. Most traditional hydropower facilities are found in hilly or mountainous areas. New hydropower uses energy from the natural movement of water to produce electricity without changing the water flow. For example, the constant flow of water in a river can spin the blades of underwater turbines to produce electricity.

Solar power is generated when special panels of solar cells, or modules, capture sunlight and convert it directly into electricity. The electricity produced by solar panels can be used right away, fed into the power grid for others to use, or stored in a battery so it is also available on cloudy days. Solar thin films are light-absorbing materials that are rolled, sprayed, or painted onto rooftops and other surfaces. Thermal solar power uses mirrors or panels containing tiny tubes filled with water that absorb heat from the sun. On rooftops, they can supply hot water for individual buildings. Concentrated solar power can also be used to create steam that spins turbines at electric power plants.

Solar power is generated when special panels of solar cells, or modules, capture sunlight and convert it directly into electricity. The electricity produced by solar panels can be used right away, fed into the power grid for others to use, or stored in a battery so it is also available on cloudy days. Solar thin films are light-absorbing materials that are rolled, sprayed, or painted onto rooftops and other surfaces. Thermal solar power uses mirrors or panels containing tiny tubes filled with water that absorb heat from the sun. On rooftops, they can supply hot water for individual buildings. Concentrated solar power can also be used to create steam that spins turbines at electric power plants.

Wind energy is one of the world’s fastest-growing sources of renewable energy. As wind passes through the blades of a windmill, the blades spin. The shaft that is attached to the blades turns and powers a pump or turns a generator to produce electricity. Electricity is then stored in batteries. The speed of the wind and the size of the blades determine how much energy can be produced. Wind energy is more efficient in windier parts of the country. Most wind power is produced from wind farms—large groups of turbines located in consistently windy locations. Small wind turbines can be used for individual homes, businesses, and boats. They can be used to pump water, or the electricity can be stored in large batteries for use at another time. Wind, used as a fuel, is free and non-polluting and produces no emissions or chemical wastes.

Wind energy is one of the world’s fastest-growing sources of renewable energy. As wind passes through the blades of a windmill, the blades spin. The shaft that is attached to the blades turns and powers a pump or turns a generator to produce electricity. Electricity is then stored in batteries. The speed of the wind and the size of the blades determine how much energy can be produced. Wind energy is more efficient in windier parts of the country. Most wind power is produced from wind farms—large groups of turbines located in consistently windy locations. Small wind turbines can be used for individual homes, businesses, and boats. They can be used to pump water, or the electricity can be stored in large batteries for use at another time. Wind, used as a fuel, is free and non-polluting and produces no emissions or chemical wastes.

Fuel cells are electrochemical devices that produce electricity through a chemical reaction. Fuel cells are rechargeable, contain no moving parts, are clean, and produce no noise. Scientists are exploring ways that they could be used as a power source for nearly exhaust-free automobiles and how they can be used as electricity-generating plants. The high cost of manufacturing fuel cells has prevented the mass use of this valuable energy source.

Fuel cells are electrochemical devices that produce electricity through a chemical reaction. Fuel cells are rechargeable, contain no moving parts, are clean, and produce no noise. Scientists are exploring ways that they could be used as a power source for nearly exhaust-free automobiles and how they can be used as electricity-generating plants. The high cost of manufacturing fuel cells has prevented the mass use of this valuable energy source.

Ocean sources. Oceans, which cover more than 70% of the earth, contain both thermal energy from the sun’s heat and mechanical energy from the tides and waves. Ocean thermal energy conversion (OTEC) converts solar radiation to electric power. OTEC power plants use the difference in temperature between warm surface waters heated by the sun and colder waters found at ocean depths to generate electricity. Tidal energy works from the power of changing tides, but it needs large tidal differences. The tidal process utilizes the natural motion of the tides to fill reservoirs, which are then slowly discharged through electricity-producing turbines. Wave energy extracts energy from surface waves, from pressure fluctuations below the water surface, or from the full wave, and uses the interaction of winds with the ocean surface. This technology is still in the exploratory phases in the United States.

Ocean sources. Oceans, which cover more than 70% of the earth, contain both thermal energy from the sun’s heat and mechanical energy from the tides and waves. Ocean thermal energy conversion (OTEC) converts solar radiation to electric power. OTEC power plants use the difference in temperature between warm surface waters heated by the sun and colder waters found at ocean depths to generate electricity. Tidal energy works from the power of changing tides, but it needs large tidal differences. The tidal process utilizes the natural motion of the tides to fill reservoirs, which are then slowly discharged through electricity-producing turbines. Wave energy extracts energy from surface waves, from pressure fluctuations below the water surface, or from the full wave, and uses the interaction of winds with the ocean surface. This technology is still in the exploratory phases in the United States.

Alternative fuel vehicles are designed to run on fuels other than gasoline or diesel fuel. Some of these vehicles are already on the road. Others are still in the research and development stage. As increasing numbers of vehicle companies are making alternative fuel vehicles, and research and development into them continues, fuel efficiency, driving range, and speed capacities are likely to improve.

Electric Vehicles

Electric vehicles (EVs) include cars, trucks, vans, buses, trolleys, light-rail, subways, and bicycles. All EVs have an electric motor that turns the wheels and a lead acid, nickel cadmium, or nickel metal hydride battery to run the motor. Most EVs employ regenerative braking, which allows some of the kinetic energy to be stored in the vehicle while decelerating. To accomplish this, the motor is operated as a generator, providing braking torque to the wheels and recharging the traction batteries. This energy can then be used for propulsion or to power vehicle accessories.

Hybrid electric vehicles (HEVs) have batteries to provide electric power, plus a small internal combustion engine usually powered by gasoline of diesel. The batteries get recharged from the gasoline or diesel engine, which shuts down completely at stoplights. While braking, kinetic energy is converted into electricity and then stored in the battery.

Battery Electric Vehicles

Battery EVs run entirely on electrical energy. Instead of a fuel tank, batteries store the electricity that is used to operate the vehicle. These batteries can be recharged by plugging the vehicle into a special high-voltage charging station or standard 120-volt or 240-volt household outlets. It takes anywhere from 2 to about 20 hours to recharge the battery, depending on the vehicle’s charger and the voltage used. The batteries store the electricity until the vehicle is driven.

Battery EVs run entirely on electrical energy. Instead of a fuel tank, batteries store the electricity that is used to operate the vehicle. These batteries can be recharged by plugging the vehicle into a special high-voltage charging station or standard 120-volt or 240-volt household outlets. It takes anywhere from 2 to about 20 hours to recharge the battery, depending on the vehicle’s charger and the voltage used. The batteries store the electricity until the vehicle is driven.

Early types of battery EVs included golf carts, scooters, and other vehicles used for short trips at low speeds. With rapid industry growth this decade, battery EVs can accommodate both city and highway driving needs. Smaller models designed for urban use can travel 30-75 mph and go 50-85 miles on a charge. The high-end Tesla can reach speeds of 150 mph and travel more than 300 miles on a single charge.

Under the hood, a battery EV consists of an electric motor, one or more controllers, and batteries. The controller governs the amount of electricity that flows from the batteries to the motor when the driver steps on the accelerator. The motor changes electrical energy from the batteries to mechanical energy, which makes the vehicle move.

Driving a battery EV down the road produces no pollution at all. Even when pollution related to power plant electricity production is factored in, these EVs produce less pollution than gasoline- or diesel-powered vehicles. Battery EVs are also more efficient than gasoline or diesel vehicles, if you compare the energy used in creating gasoline at a refinery to producing electricity in a power plant.

When a battery EV is stopped in traffic, it doesn’t have to use fuel to keep the motor running like a gasoline engine does. Added efficiency is created by something called “regenerative braking.” When the vehicle slows down, the motor continues to turn, but the power no longer flows to the wheels. Instead, the power is fed back to the batteries, giving them a small charge every time the driver stops or goes downhill.

Hybrid Electric Vehicles

A hybrid vehicle is any vehicle that uses two or more power sources. The most common hybrids on the road today are gasoline-electric hybrids, also called hybrid EVs. A gasoline engine and an electric motor power these vehicles.

A hybrid vehicle is any vehicle that uses two or more power sources. The most common hybrids on the road today are gasoline-electric hybrids, also called hybrid EVs. A gasoline engine and an electric motor power these vehicles.

Since 1999, when hybrid electric vehicles first appeared on the market, automakers have been busy designing and building new models. There are now over 60 models of HEVs on the market, with the Toyota Prius remaining the top-selling HEV since its introduction in 2000.

The major components of an HEV include a gasoline engine, an electric motor, a transmission, and, in some models, a generator. A fuel tank stores gasoline for the engine, and a battery pack stores electricity for the motor. The battery is charged by the gasoline engine and by the electric motor or generator during normal operation. Regenerative braking charges the batteries slightly when the car slows down, recovering some of the energy.

Plug-in Hybrid Electric Vehicles

Another type of hybrid electric vehicle is the plug-in hybrid, or PHEV, which uses both gasoline and electricity. These vehicles have two power systems, an internal combustion engine and a battery. Unlike the regular hybrids such as the Toyota Prius, the PHEV’s battery can be recharged either by the gas engine or by plugging the vehicle into an external source of electricity. Some PHEVs are known as extended-range electric vehicles, or EREVs, because their secondary power source provides enough fuel to allow the vehicle to drive hundreds of miles when the batteries become low.

All types of hybrid EVs use smaller, more efficient gasoline engines than conventional gasoline or diesel vehicles. They also burn less fuel than conventional vehicles, thus producing fewer pollutants and releasing less carbon dioxide into the air.

Natural Gas Vehicles

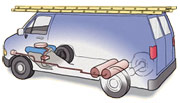

Vehicles that run on natural gas instead of gasoline are called natural gas vehicles (NGVs). Natural gas that has been compressed into special high-pressure cylinders to get more volume into a smaller amount of space is called compressed natural gas, or CNG. Some NGVs run on CNG only, and others can run on either CNG or gasoline. Some long-haul trucks and transit buses run on liquefied natural gas, or LNG, which is made by cooling natural gas to condense it into a liquid.

Vehicles that run on natural gas instead of gasoline are called natural gas vehicles (NGVs). Natural gas that has been compressed into special high-pressure cylinders to get more volume into a smaller amount of space is called compressed natural gas, or CNG. Some NGVs run on CNG only, and others can run on either CNG or gasoline. Some long-haul trucks and transit buses run on liquefied natural gas, or LNG, which is made by cooling natural gas to condense it into a liquid.

When the engine of an NGV is started, natural gas flows into a fuel line, and then enters a regulator where the gas pressure is reduced. A fuel injection system mixes the gas with air and feeds the mixture into the engine. The fuel-air mixture is adjusted to burn efficiently and with the least possible emissions. Natural gas burns in the engine just like gasoline.

NGVs produce fewer pollutants than gasoline or diesel vehicles and cost less to maintain. The tanks used to store natural gas can withstand crashes and heat far better than most gasoline tanks can. In the event of a crash, natural gas disperses into the air, unlike gasoline, which pools on the ground and creates a fire hazard.

Fuel-Cell Vehicles

Fuel-cell vehicles (FCVs), currently in development, are powered by hydrogen fuel cells. Fuel cells produce electricity by combining oxygen with hydrogen. A fuel-cell car would operate much like an EV, except that it would depend on a supply of hydrogen, rather than a battery pack, for power.

Fuel-cell vehicles (FCVs), currently in development, are powered by hydrogen fuel cells. Fuel cells produce electricity by combining oxygen with hydrogen. A fuel-cell car would operate much like an EV, except that it would depend on a supply of hydrogen, rather than a battery pack, for power.

The components of one prototype FCV include three stacks of fuel cells, a tank of hydrogen, an electric motor, and an inverter. The fuel cells operate something like batteries in reverse. Inside each fuel cell, hydrogen and oxygen from the air are combined in a reaction that splits the molecules into protons and electrons and produces electric current. The inverter changes the direct current produced by the fuel cell into alternating current that powers the electric motor, which turns the vehicle’s wheels. The electric current also charges a conventional car battery that powers the car’s lights, radio, air conditioning, and so on.

FCVs are twice as efficient as gasoline or diesel engines, and they produce no pollutants or carbon dioxide. The only tailpipe emission is water vapor. The biggest challenge now facing the developers of FCVs is where to get the hydrogen.

Hydrogen can be produced from a variety of resources, including fossil fuels, nuclear energy, biomass, and other renewable energy technologies. The environmental impact and energy efficiency of hydrogen depends greatly on how it is produced. At the present time, fossil fuels are the most convenient source of hydrogen. But using fossil fuels to produce hydrogen creates pollution and adds to the consumption of nonrenewable resources.

Alternative sources of hydrogen include plant crops, agricultural waste, and wastewater from food processing plants. But, at least so far, so much energy is required to extract hydrogen from these sources that it becomes too expensive to use as a vehicle fuel. FCVs that arrive on the market in the next few years probably will use hydrogen-rich fuels such as methanol, natural gas, or even gasoline, but these fuels must first be converted into pure hydrogen gas by an onboard device called a reformer. The long-term goal is to find more effective and efficient ways to produce and store hydrogen.

Biodiesel Vehicles

Biodiesel is a fuel that can be made from vegetable oils, recycled cooking oils from fast food restaurants, and certain animal fats, such as fish oil or beef tallow. Biodiesel can be used in any diesel engine in place of diesel fuel. No engine modification is necessary, because diesel engines were originally designed to run on a variety of fuels, including vegetable oils.

Biodiesel is a fuel that can be made from vegetable oils, recycled cooking oils from fast food restaurants, and certain animal fats, such as fish oil or beef tallow. Biodiesel can be used in any diesel engine in place of diesel fuel. No engine modification is necessary, because diesel engines were originally designed to run on a variety of fuels, including vegetable oils.

Biodiesel is easy to make and store, and is safer to transport than diesel fuel. It helps increase engine life. Using it reduces the consumption of fossil fuels. Compared to diesel fuel, biodiesel produces almost no pollutants and significantly reduces carbon dioxide emissions. It’s also more pleasant to use—the exhaust from a biodiesel vehicle often smells like popcorn or French fries! In some regions of the United States, biodiesel is becoming popular as a fuel for agricultural equipment, such as tractors and trucks, as well as for passenger vehicles.

People-Powered Vehicles

In many parts of the world, especially in places where vehicles and fuel are expensive and difficult to obtain, people depend on their own two feet for transportation. Wheelbarrows, rickshaws, and bicycles are just a few examples of transportation devices that run solely on people power.

In many parts of the world, especially in places where vehicles and fuel are expensive and difficult to obtain, people depend on their own two feet for transportation. Wheelbarrows, rickshaws, and bicycles are just a few examples of transportation devices that run solely on people power.

Using people power whenever possible makes a lot of sense. Walking and bicycling produce no pollutants and help keep the environment healthy. They also contribute to personal health—getting plenty of exercise can lengthen a person’s life span and help avoid health problems like obesity and heart disease. And people are easy to fuel—all it takes is food!

Careers in Electricity and Natural Gas

Electric Industry Careers

Electric power generating plant operators control or operate machinery, such as stream-driven turbine generators, to generate electric power, often through the use of control boards or semi-automatic equipment. Electric power plant operators control and monitor boilers, turbines, generators, and auxiliary equipment in power generating plants. Operators distribute power demands among generators, combine the current from several generators, and monitor instruments to maintain voltage and regulate electricity flows from the plant. When power requirements change, these workers start or stop generators and connect or disconnect them from circuits. They may use computers to keep records of switching operations and loads on generators, lines, and transformers. Operators may also use computers to prepare reports of unusual incidents, malfunctioning equipment, or maintenance performed during their shift.

Electric power generating plant operators control or operate machinery, such as stream-driven turbine generators, to generate electric power, often through the use of control boards or semi-automatic equipment. Electric power plant operators control and monitor boilers, turbines, generators, and auxiliary equipment in power generating plants. Operators distribute power demands among generators, combine the current from several generators, and monitor instruments to maintain voltage and regulate electricity flows from the plant. When power requirements change, these workers start or stop generators and connect or disconnect them from circuits. They may use computers to keep records of switching operations and loads on generators, lines, and transformers. Operators may also use computers to prepare reports of unusual incidents, malfunctioning equipment, or maintenance performed during their shift.

Power distributors and dispatchers coordinate, regulate, or distribute electricity or steam in generating stations, over transmission lines to substations, and over electric power lines. Also called load dispatchers or systems operators, these workers control the flow of electricity through transmission lines to industrial plants and substations that supply residential electric needs. They operate current converters, voltage transformers, and circuit breakers. Dispatchers monitor equipment and record readings at a pilot board, which is a map of the transmission grid system showing the status of transmission circuits and connections with substations and industrial plants.

Power distributors and dispatchers coordinate, regulate, or distribute electricity or steam in generating stations, over transmission lines to substations, and over electric power lines. Also called load dispatchers or systems operators, these workers control the flow of electricity through transmission lines to industrial plants and substations that supply residential electric needs. They operate current converters, voltage transformers, and circuit breakers. Dispatchers monitor equipment and record readings at a pilot board, which is a map of the transmission grid system showing the status of transmission circuits and connections with substations and industrial plants.

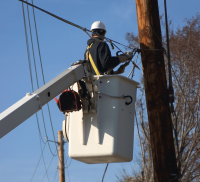

Line installers and repairers install and repair cables or wires used in electrical power or distribution systems. They install insulators, wooden poles, and light or heavy-duty transmission towers. Blue-collar worker supervisors directly supervise and coordinate the activities of production workers. These supervisors ensure that workers, equipment, and materials are used and maintained properly and efficiently to maximize productivity.

Line installers and repairers install and repair cables or wires used in electrical power or distribution systems. They install insulators, wooden poles, and light or heavy-duty transmission towers. Blue-collar worker supervisors directly supervise and coordinate the activities of production workers. These supervisors ensure that workers, equipment, and materials are used and maintained properly and efficiently to maximize productivity.

Industrial machinery repairers install, repair, and maintain machinery in power generating stations, gas plants, and water treatment plants. They repair and maintain the mechanical components of generators, waterwheels, water-inlet controls, and piping in generating stations; steam boilers, condensers, pumps, compressors, and similar equipment in gas manufacturing plants; and equipment used to process and distribute water for public and industrial uses.

Maintenance mechanics perform work involving a variety of maintenance skills to keep machines, mechanical equipment, and the structure of an establishment in repair. They are generally found in small establishments, and their duties may involve pipefitting, boilermaking, electrical work, carpentry, welding, and installing new equipment.

Administrative support occupations account for about one-fifth of the jobs in the utilities industry. These occupations include customer service representatives, general office clerks, meter readers, and financial records processing occupations. Customer service representatives interview applicants for water, gas, and electric service. They talk with customers by phone or in person and receive orders for installation, turn-on, discontinuance, or change in service. General office clerks may do bookkeeping, typing, stenography, office machine operation, and filing. Meter readers read electric, gas, water, or steam consumption meters visually or remotely using radio transmitters and record the volume used by residential and industrial customers. Financial records processing occupations, such as billing, cost, and rate clerks, compile data, compute fees and charges, and prepare invoices for billing purposes, in addition to the routine calculating, posting, and verifying duties necessary to keep financial records complete.

Operator, fabricator, and laborer occupations include helpers, the entry-level occupation in almost all utilities occupations tied to production activities. Other helpers include refuse collectors, who collect and dump refuse from containers into a truck. Material moving equipment operators distribute refuse around landfills and ensure that the refuse is covered by the necessary amount of soil or cover each day. Truck drivers operate refuse collection trucks that are either self-loading or loaded by refuse collectors.

Operator, fabricator, and laborer occupations include helpers, the entry-level occupation in almost all utilities occupations tied to production activities. Other helpers include refuse collectors, who collect and dump refuse from containers into a truck. Material moving equipment operators distribute refuse around landfills and ensure that the refuse is covered by the necessary amount of soil or cover each day. Truck drivers operate refuse collection trucks that are either self-loading or loaded by refuse collectors.

Executives, managers, and administrators in the utilities industry plan, organize, direct, and coordinate management activities. They are often responsible for maintaining an adequate supply of electricity, gas, water, steam, or sanitation service.

Professional specialty occupations in this industry include engineers and computer systems analysts, engineers, and scientists. Engineers develop technologies that allow, for example, utilities to produce and transmit gas and electricity more efficiently and water more cleanly. They may also develop improved methods of landfill or wastewater treatment operations in order to maintain compliance with government regulations. Electrical and mechanical engineers design electric power distribution systems and power plants.

Computer systems analysts, engineers, and scientists develop computer systems to automate utility processes, provide plant simulators for operator training, and improve operator decision making.

Technicians account for only a small proportion of total employment in this industry. Technician occupations include engineering and science technicians who assist engineers in research activities and may conduct some research independently.

Natural Gas Industry Careers

Petroleum engineers are responsible for planning and supervising the actual drilling operation, once a potential drill site has been located. These engineers develop and implement the most efficient recovery method, in order to achieve maximum profitable recovery. They also plan and supervise well operation and maintenance. Drilling superintendents serve as supervisors of drilling crews, supervising one or more drilling rigs.

Rotary drilling crews usually consist of four or five workers. Rotary drillers supervise the crew and operate machinery that controls drilling speed and pressure. Rotary-rig engine operators are in charge of engines that provide the power for drilling and hoisting. Second in charge, derrick operators work on small platforms high on rigs to help run pipe in and out of well holes and operate the pumps that circulate mud through the pipe. Rotary-driller helpers, also known as roughnecks, guide the lower ends of pipe to well openings and connect pipe joints and drill bits.

Rotary drilling crews usually consist of four or five workers. Rotary drillers supervise the crew and operate machinery that controls drilling speed and pressure. Rotary-rig engine operators are in charge of engines that provide the power for drilling and hoisting. Second in charge, derrick operators work on small platforms high on rigs to help run pipe in and out of well holes and operate the pumps that circulate mud through the pipe. Rotary-driller helpers, also known as roughnecks, guide the lower ends of pipe to well openings and connect pipe joints and drill bits.

Most workers involved in gas processing are operators. Gas treaters tend automatically controlled treating units that remove water and other impurities from natural gas. Gas-pumping-station operators tend compressors that raise the pressure of gas for transmission in pipelines. Both types of workers can be assisted by gas-compressor operators.

Many employees in large natural gas processing plants—welders, electricians, instrument repairers, and laborers, for example—perform maintenance activities. In contrast, many small plants are automated and are checked at periodic intervals by maintenance workers or operators, or monitored by instruments that alert operators if trouble develops. In non-automated plants, workers usually combine the skills of both operators and maintenance workers.

Many employees in large natural gas processing plants—welders, electricians, instrument repairers, and laborers, for example—perform maintenance activities. In contrast, many small plants are automated and are checked at periodic intervals by maintenance workers or operators, or monitored by instruments that alert operators if trouble develops. In non-automated plants, workers usually combine the skills of both operators and maintenance workers.

Gas plant operators operate gas liquefying and regasification equipment, operate compressors to control gas pressure in transmission pipelines, and coordinate injections and withdrawals at storage fields.

Source: U.S. Department of Labor Occupational Outlook Handbook.

Ideas for Further Research

- Do some research to find an example of someone who survived an electric shock from a power line or an electric appliance. How did the incident happen? How could it have been prevented?

- Research efforts around the country to protect various forms of wildlife from electric power lines.

- Learn about AC and DC current. Why is AC current so much more dangerous to contact?

- Find out how utility line workers protect themselves when working around power lines. What type of clothing, vehicles, and equipment do they use? What type of training do they receive?

- Find some stories about people who have been injured or killed by mixing water and electricity. Examples: stepping in a puddle with a fallen power line in it, or using a hair dryer in the bathtub and dropping it in the water. Why were these actions so dangerous? What lessons can be learned?

- What are some things you can do around your home to make it safer regarding water and electricity? Report to the class about a safety measure that you have taken at home.

- Interview an electrician. What kind of training is required? What kind of licensing? Has she or he ever been shocked? How?

- Has anyone in your community been struck by lightning? What were the circumstances? How was the person affected? How could the strike have been prevented?

- Find out where most of the natural gas is found that we currently use in the United States.

- Do some research to find out whether gas is heavier than air. What does this tell you about where most natural gas will collect in the event of a gas leak in your home?