Natural Gas FAQ (Frequently Asked Questions)

More homes in the U.S. are heated by natural gas than by electricity.

History Zone

The Chinese discovered natural gas in 600 BC, but it wasn’t until the 1950s that natural gas pipelines were built for widespread use of natural gas in the United States. Here’s what happened in between.

600 BC

First Recorded Use of Natural Gas

The ancient Chinese were the first to discover underground deposits of natural gas. In 600 BC, Confucius wrote of wells 100 feet deep yielding water and natural gas along the Tibetan border. The Chinese piped the gas to where it was needed through long, hollow bamboo poles.

100 AD

First Use of Natural Gas in the Home

The first recorded use of natural gas in the home was in Persia (now Iran) around the first century AD. Natural gas seeped out of the ground and was ignited by lightning, producing a hot flame that burned continuously, day and night. The King of Persia decided to take advantage of this “eternal flame.” But instead of having the gas piped to his home—like we do today—he built his royal kitchen near the flame.

1626

Natural Gas Use in America

Natural gas usage was identified in America as early as 1626, when French explorers found Native Americans igniting gases that were seeping into and around Lake Erie.

1800s

Natural Gas Street Lights

For most of the 1800s, natural gas was used as a fuel for lamps. There were no pipelines to bring gas into individual buildings, so most of the gas went to light city streets. After the 1890s, cities began using electricity for their streetlights, so gas producers began searching for new uses for their product.

1821

First Natural Gas Well in U.S.

In 1821, a gunsmith named William Hart drilled the first natural gas well outside Fredonia, New York, near Lake Erie. He dug down 27 feet. (Today’s wells go down more than 30,000 feet!) Hart is considered by many to be the “father of natural gas” in the United States. In 1858, he formed the Fredonia Gas Light Company, the nation’s first natural gas company.

1859

First Natural Gas Pipeline in U.S.

In 1859, Colonel Edwin Drake drilled a 69-foot well in Pennsylvania that struck natural gas and oil. Later, a 5½-mile-long, 2-inch-diameter pipeline was constructed, running from the well to the town of Titusville. Many consider this first gas transportation pipeline to be the start of the natural gas industry in this country.

1885

First Gas Burners

Ever heard of a Bunsen burner? Robert Bunsen was a German scientist who made popular a burner that mixed air with natural gas, thus allowing the natural gas flame to be regulated. This made it more convenient to use natural gas for heating buildings and cooking.

1940s to Present

Widespread Construction of Gas Pipelines

Improvements in metals, pipe making, and welding techniques during World War II made pipeline construction more economically attractive. After the war, the nation began building its pipeline network. In the 1950s and 1960s, thousands of miles of natural gas pipeline were constructed throughout the United States. Today, this interstate pipeline system contains over one million miles of pipe—enough to stretch to the moon and back twice.

Natural Gas Vehicles

Vehicles that run on natural gas instead of gasoline are called natural gas vehicles (NGVs). There are about 112,000 NGVs on our nation’s roads today and over 13 million worldwide. More than 30 different manufacturers produce NGVs.

Many passenger vehicles are available today that run on natural gas that has been compressed into special high-pressure cylinders to get more volume into a smaller amount of space (called compressed natural gas, or CNG). CNG is available at special fueling stations.

Some vehicles run on CNG only, and others can run on either CNG or gasoline; these are called bi-fuel vehicles. Some long-haul trucks and transit buses run on a different form of natural gas called liquefied natural gas, or LNG, which is made by refrigerating natural gas to condense it into a liquid.

The liquid form is much more dense than natural gas or CNG, and thus has much more energy for the amount of space it takes up. So, more energy can be stored in the same amount of space on a car or truck. That means LNG is good for large trucks that need to go a long distance before they stop for more fuel.

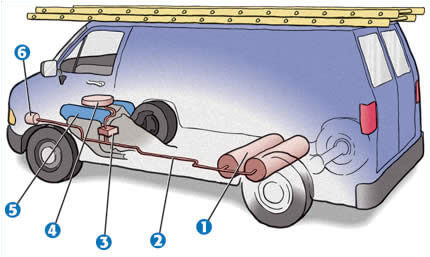

Here is how NGVs work:

- NGVs burn natural gas that is compressed and stored in cylinders.

- When the engine is started, natural gas flows into a fuel line.

- The gas then enters a regulator where its pressure is reduced.

- The natural gas feeds into the engine through a fuel injection system where it’s combined with air. The fuel-air mixture is adjusted to burn most efficiently and with the least possible emissions.

- Natural gas burns in the engine just like gasoline.

- NGVs can be refueled by attaching a hose at the fueling point.

NGVs are a popular transportation choice because they run cleaner than other vehicles. Compared to gasoline- or diesel-powered vehicles, they produce much lower levels of pollutants and cost less to maintain. Also, natural gas costs, on average, one-third less than conventional gasoline at the pump. The tanks used to store natural gas can withstand crashes and heat far better than most gasoline tanks can. In the event of a crash, natural gas disperses into the air, whereas gasoline pools on the ground, creating a fire hazard.

Natural Gas Careers

Photogrammetrists

These mapping scientists use aerial photos to make drawings of the earth’s surface and subsurface. They use Global Positioning System (GPS) technology, which relies on satellites to send radio signals to special instruments on the earth’s surface. The instruments, which receive signals from several satellites simultaneously, help photogrammetrists draw the most accurate picture possible. Geophysical prospecting surveyors help photogrammetrists develop maps to help locate natural gas deposits.

Seismologists

These engineers analyze the patterns that result as sound waves are forced deep into the earth. The way the sound waves bounce back reflects rock formations that are likely to hold natural gas.

Petroleum Engineers

These engineers search the world for reservoirs containing oil or natural gas. Once these are discovered, petroleum engineers work with geologists and other specialists to understand the geologic formation and properties of the rock containing the reservoir, determine the drilling methods to be used, and monitor drilling and production operations. They design equipment and processes to achieve the maximum profitable recovery of oil and natural gas. Petroleum engineers rely heavily on computer models to simulate the effects of various drilling options.

Rotary Drillers

Rotary drilling crews usually consist of four or five workers who operate large machinery involved in drilling for natural gas. Rotary drillers supervise the crew and operate machinery that controls drilling speed and pressure. Rotary-driller helpers guide the lower ends of pipe to well openings and connect pipe joints and drill bits. Rotary-rig engine operators are in charge of engines that provide the power for drilling and hoisting. Derrick operators work on small platforms high on rigs to help run pipe in and out of well holes and operate the pumps that circulate mud through the pipe.

Natural Gas Processing Workers

Most workers involved in natural gas processing are equipment operators. Wellhead pumpers operate power pumps and auxiliary equipment to produce the flow of oil or natural gas from wells in oil fields. Gas treaters tend automatically controlled treating units that remove water and other impurities from natural gas. Gas compressor and gas pumping station operators operate steam, gas, electric motor, or internal combustion engine driven compressors. They transmit, compress, or recover gases, such as butane, nitrogen, hydrogen, and natural gas. Gas plant operators operate gas liquefying equipment, operate compressors to control gas pressure in transmission pipelines, and coordinate injections and withdrawals at storage fields.

Maintenance Workers

Many employees in large natural gas processing plants—welders, electricians, instrument repairers, and laborers, for example—perform maintenance activities. In contrast, many small plants are automated and are checked at periodic intervals by maintenance workers or operators, or monitored by instruments that alert operators if trouble develops. In non-automated plants, workers usually combine the skills of both operators and maintenance workers. Gas service dispatchers monitor natural gas lines and send out service trucks and crews to take care of emergencies.

Heating Equipment Technicians

These workers follow blueprints or other specifications to install heating systems. After putting the equipment in place, they install fuel and water supply lines, air ducts and vents, pumps, and other components. They may connect electrical wiring and controls and check the unit for proper operation. To ensure the proper functioning of the system, furnace installers often use combustion test equipment such as carbon dioxide, carbon monoxide, and oxygen testers. After a furnace has been installed, heating equipment technicians often perform routine maintenance and repair work to keep the system operating efficiently.

Natural Gas Appliance Repair Technicians

These technicians visually inspect appliances and check for unusual noises, excessive vibration, fluid leaks, or loose parts to determine why they fail to operate properly. They use service manuals, troubleshooting guides, and experience to diagnose particularly difficult problems. They disassemble the appliance to examine its internal parts for signs of wear or corrosion. Repairers follow wiring diagrams and use testing devices to check electrical systems for shorts and faulty connections. After identifying problems, they replace or repair defective belts, motors, heating elements, switches, gears, or other items. They tighten, align, clean, and lubricate parts as necessary. Repairers use common hand tools, including screwdrivers, wrenches, files, and pliers, as well as soldering guns and special tools designed for particular appliances. When repairing appliances with electronic parts, they may replace circuit boards or other electronic components.

Much of this information comes from the U.S. Department of Labor Occupational Outlook Handbook, which can be accessed via www.bls.gov/ooh.